STUDER A820 Specifications

- Tape speeds

- 30 - 15 - 7.5 - 3.75 ips

- (76.2 - 38.1 - 19.05 - 9.525 cm/s)

- Equalization

- NAB

- CCIR

- Variable speed

- +/- 7 semitones from nominal (+54%, -33%)

- Display in %, half-tones, or IPS

- Programmable

- Tape speed deviation

- +/- 0.2% max

- Tape slip

- 0.1% max

- Tape reels

- NAB

- Cine

- DIN

- 14-inch max reel diam

- 1.77-inch min hub diam

- Tape width

- 1/4-inch (6.35 mm)

- 1/2-inch (12.7 mm)

- Convertible

- Automatic switchover of tape tensions and audio alignment

- Wow and flutter

- 30 ips - 0.03% max

- 15 ips - 0.04% max

- 7.5 ips - 0.06% max

- 3.75 ips - 0.1% max

- Start time

- 15 ips - 0.5 sec (1000m on DIN hub, 2500 ft on NAB hub)

- Winding speed

- 4-590 ips (0.1 - 15 m/s)

- Automatic speed reduction at end of tape

- Winding time

- 90 sec for 1000 m tape

- 44 sec for 2500 ft tape

- Stopping time

- 4 sec (full 1000 m reel, 1/4-inch tape)

- Tape tension (measured at left reel)

- 1/4-inch Repro/Record

- 0.7 N (0.5 - 1.8 N range)

- 1/4-inch Winding

- 0.8 N (0.5 - 1.7 N range)

- 1/2-inch Repro/Record

- 1.2 N (0.5 - 1.8 N range)

- 1/2-inch Winding

- 0.9 N (0.5 - 1.7 N range)

- 1/4-inch Repro/Record

- Inputs (trafoless)

- Impedance > 20 kOhm (30 - 20,000 Hz)

- Inputs (transformer)

- Impedance > 10 kOhm (30 - 20,000 Hz)

- Outputs (trafoless)

- Impedance < 30 Ohm (30 - 20,000 Hz). Load > 200 Ohm

- Outputs (transformer)

- Impedance < 50 Ohm (30 - 20,000 Hz), Load > 200 Ohm

- Equalization

- NAB or CCIR

- Switch selectable

- Frequency Response (+/- 2 dB)

- 30 ips - 40 - 22,000 Hz

- 15 ips - 30 - 20,000 Hz

- 7.5 ips - 30 - 16,000 Hz

- 3.75 ips - 30 - 10,000 Hz

- Frequency Response (+/- 1 dB)

- 30 ips - 60 - 20,000 Hz

- 15 ips - 30 - 18,000 Hz

- 7.5 ips - 30 - 12,000 Hz

- 3.75 ips - 30 - 8,000 Hz

- Signal-to-Noise NAB (1/4-inch two-track 2.0 mm track, RMS, A-weighted)

- 30 ips - 75 dB

- 15 ips - 72 dB

- 7.5 ips - 73 dB

- 3.75 ips - 64 dB

- Signal-to-Noise NAB (1/2-inch, two-track, 5.0 mm track width, RMS A-weighted)

- 30 ips - 77 dB

- 15 ips - 75 dB

- 7.5 ips - 76 dB

- Cross-Talk (at 1 kHz)

- Stereo > 55 dB

- Two-track > 65 dB

- Power Consumption

- Stop (no load) - 80 W

- Play on 2 channels - 130 W

- Spooling - 160 W

- Max - 450 W

- Disturbed Operation

- 100 msec transient line voltage failure

- Ambient Temperature

- 0 - 40C (32 - 104F)

- Relative Humidity

- 20 - 90%, non-condensing

- Weight

- 91 kg (200.2 lb) net

- Dimensions

- Depth - 656 mm

- Width - 700 mm

- Width - 750 mm (14-inch reels)

- Height - 1330 mm (with castors)

- Rear clearance for tilt - 300 mm approx

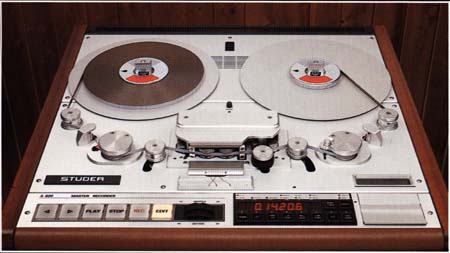

STUDER A820 Master Recorder

There is a surprising paucity of Information about the STUDER A820 on the web - even photos are scarce. We hope that this webpage will help raise awareness of the STUDER A820 as one of the best machines for archival preservation work, and why we have chosen to standardize upon it at The Audio Archive.

The text and images below are taken from a vintage 1980s STUDER A820 Professional Tape Recorder brochure. Copyright WILLI STUDER AG, CH-8105 Regensdorf-Zurich, Switzerland.

Rather than simply scan the brochure, we transcribe the text in its entirety so that it is searchable from The Audio Archive search box on this webpage. In a few places, we do make comments and highlight features of the STUDER A820 - these comments and highlights are in an alternative color.

This is not your typical marketing brochure. STUDER clearly has the heart and mind of an engineering company - the STUDER machines were made by tape recording perfectionists, for tape recording perfectionists. Rather than hyperbole, the brochure reads more like an introduction to an operating manual or a product management MRD (Marketing Requirements Document). The German-to-English translation by STUDER is a bit clumsy at times, but still very readable and immensely informative.

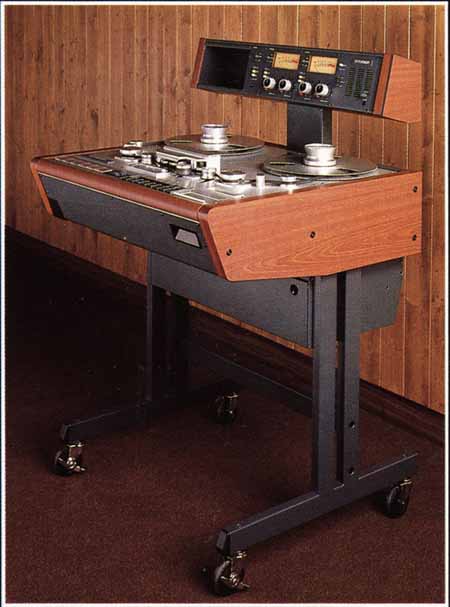

Elegant design with slim transport for adequate legroom and operator convenience. The Audio Archive: What the brochure does not tell you is how flimsy the stand is considering it is holding a nearly 200-pound tape transport. We never sit at our machines - but that it is because for archival work we do not do any analog editing.

STUDER A820 Analog Master Recorder

STUDER combines state-of-the-art technology, Swiss craftsmanship and years of experience in recorder design

STUDER's Trend-Setting New Standard in the World of Analog Audio Recorders

Generations of top-premium STUDER tape recorders have influenced the history of professional audio recording. Ten-thousands prove daily demanding use the validity of STUDER's long-standing business philosophy which places overriding importance on quality, reliability, and long service life. Through decades of cooperation with leading specialists from radio, television, and music recording studios, STUDER machines have been perfected into professional tools that are appreciated worldwide. This background and experience in the development and manufacturing of tape recorders which satisfy the most diverse requirements are necessary in order to produce a totally new machine generation such as the STUDER A820.

The STUDER A820 Concept for Stability, Precision, and Completely New Operating Facilities

The concept of the STUDER A820 generation is based on traditional values such as stability, precision, and ruggedness, prerequisites for maintaining demanding specifications over a long service life. The handling concept and the peripherals compatibility have also been generously enhanced in line with future requirements. Key elements are not only a superb transport with DC motors, advanced servo circuits, and flexible audio electronics but also the operating philosophy. A software concept has been developed that goes far beyond ergonomic considerations and extends not only to machine handling but also ensures optimal access and operating facilities when the STUDER A820 is interconnected in a system with other audio and video machines.

As a consequence the STUDER A820 is a truly flexible and future-safe investment.

Advanced Technology and Elegance

The structure of the STUDER A820 tape transport mechanism permits an extremely flat design and consequently provides ample legroom when the deck is built into a console. The elegant design is accentuated by wooden side panels and an unobtrusive hand rest. The complete deck can be locked in the inclined position preferred by the operator, or for maintenance.

The Audio Archive: The STUDER A820, and all tape decks for that matter, function best when the reels are absolutely horizontal and the axes of the motors are perfectly vertical. This minimizes the affects of gravity on the rotating parts, thus minimizing speed variability. The tilting deck on the STUDER A820 and its stand design is primarily ergonomic for the comfort of the operator. Except for performing maintenance and service (which is very easy with the tilting stand), we do not tilt the deck of our STUDER A820 machines.

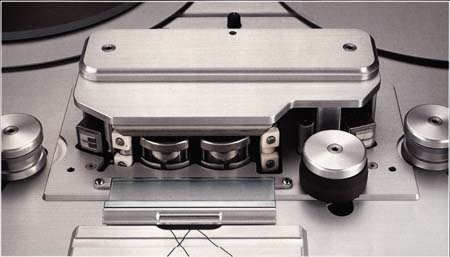

An Extremely Stable Transport Mechanism, the Result of Modern Precision Manufacturing

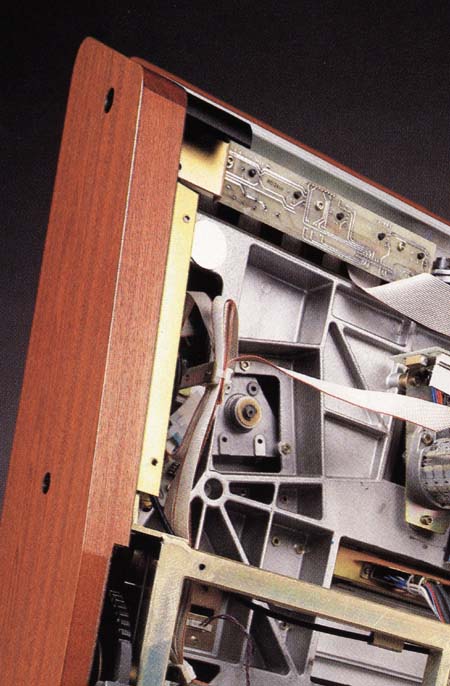

The totally new tape transport is designed for reels with a diameter of up to 14" and 1/4" or 1/2" tape. The STUDER A820 can be easily and quickly converted; only one tool is required, all screws are captive. The rigid chill-cast aluminum alloy chassis as well as the components of the mechanical assemblies have been processed on advanced CNC precision machines. This results not only in a uniformly high standard of precision for each individual machine but the state-of-the-art, numerically controlled production at Studer also ensures that mechanical assemblies can be readily replaced without loss of quality, even after many years.

Rugged construction and easy access to all building blocks are typical for STUDER equipment. The Audio Archive: You are looking at the underside of the chassis. Check out the depth of the cast webbing - 2 inches deep in places. The foundation for the transport is amazingly rigid, unlike any other tape transport. The 'built to last" philosophy is clearly visible here. It is no exaggeration to say that the world will never see a tape deck with this build quality ever again. To duplicate the STUDER A820 in small quantities today would cost hundreds-of-thousands of dollars per machine. This is truly as good as it gets - "state-of-the-art" as we like to say.

Multiprocessor Electronics Gives the Term Flexibility a New Meaning

A network of processors under control of a master processor is responsible for controlling the recorder. Each basic function has its own processor, e.g. for spooling motor and tape tension control, capstan servo or peripherals control. Because of this sophisticated combination of programmable microelectronics, advanced servo systems, and precision mechanics the STUDER A820 is a "fast", highly responsive machine that treats your valuable tapes very gently. The multiprocessor system is advantageous not only for mastering highly sensitive control mechanisms, thus permissting flexible accomodation of different fucntional sequences, but it also supports much enhanced, superflexible adaptation to diverse operating requirements through user-programmable controls.

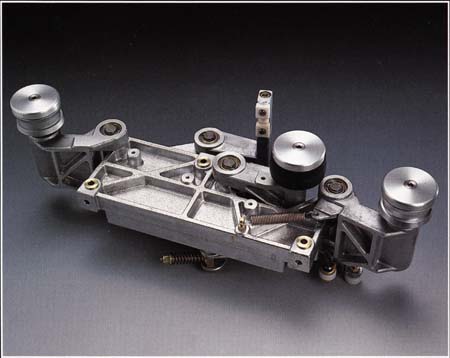

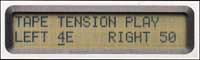

Tape tension assembly with ceramic tape guide for 1/4-inch and 1/2-inch tape. The Audio Archive: This is a STUDER A820 MKI assembly - the MKII assemblies replace the ceramic tape guide with rolling guides for even less friction (and therefore less tension) in the tape path. Once again, notice the massive casting for the arm of the tension sensor. There is no bending or vibrating, or any loss of motion information between the tape guide and the sensors, allowing for a very responsive control system.

Processor-Controlled High-Torque DC Spooling Motors

The STUDER A820 is equipped with 5 motors: 3 DC motors for the tape transport and 2 synchronous motors for the low-noise pinch roller unit. Rugged, high-torque motors with disc-type rotors featuring favorable control characteristics are used for the spooling functions; a top-quality closed-loop servo control system and a separate processor are responsible for the excellent drive characteristics and the new tape processing facilitites.

Actual values concerning tape tension, spooling motor speeds, and sense of rotation are supplied to the processor by non-contacting sensors. The reference values for tape tension and spooling speed are software-defined and stored in memory.

The processor control of the STUDER A820 automatically determines the moment of inertia of the mounted reels and optimizes from these values all acceleration and braking operations. The motor output stages equipped with power FETs operate in switched mode, very high efficiency, and correspondingly low heat dissipation; no cooling fans are required for the A820!

Processor-Controlled DC Capstan Motor with Low Rotor Mass

Through non-contacting Hall commutation, low rotor mass, and a separate processor control, the new STUDER capstan motor achieves an outstanding control behavior. This totally new development achives excellent acceleration and deceleration values. Tape stress during the start phase of PLAY mode is, for example, avoided by starting the capstan motor only when the tape contacts the capstan. However, the STUDER A820 still achieves the usual starting times because the processor control computes the optimal acceleration ramp for the mounted reels and stabilizes the motor without overshooting, and that in both direction of rotation! Needless to say that this capstan drive is eminently suited for synchronizing applications.

An additional feature of this high-quality capstan control is the trimming possibility of he nominal tape speed in very small steps of only 0.025% which means that a reference can be highly accuractly matched.

Processor-Controlled Pinch Roller Unit

The required positions of the pinch roller unit are established by 2 synchronous motors and monitored by the tape transport processor. Even in the event of a power failure the control remains responsive and can be retracted to the edit position with the energy stored in the power packs.

Pinch roller assembly: stability and ruggedness are basic ingredients for precision and long-term performance. The Audio Archive: Just like the chassis, you once again see a very thick and rigid platform for mounting the pinch roller and idlers, with cast webbing to increase stiffness without significantly increasing weight. Look at the idler arms - they even have thick cast webs.

The A820 Operating Center - Ergonomically Arranged, Easily Understandable, and Extremely Flexible

Through the extensive use of programmable microelectronics, the STUDER A820 has given the term "operating convenience" an entirely new definition because the operating procedures can be matched exactly to the user's requirements, and the comprehensive facilities very easily mastered.

The control center of the STUDER A820 - almost unlimited possibilities while maintaining simplicity - all operating keys are user programmable. The Audio Archive: The fact that you can customize all the keys and buttons on the STUDER A820 means that you can reconfigure this machine with the functions most used for archival work right at your finger tips.

Primary Tape Deck Control

The primary command keys are of the same proven design as on the STUDER A80/A800. They are illuminated and equipped with exchangeable labels because they can be freely programmed by the user.

Secondary Controls and Precision Tape Counter

Also freely programmable are the secondary controls which are equipped with exchangeable labels. More than 40 additional functions can be assigned to this key field which means tha there will be hardly be any command configuration that cannot be programmed and implemented within a very short time.

A 10-position LED window located within the secondary key field displays the digital tape time with positive or negative reading in HRS:MIN:SEC and also 1/10 SEC (display of FRAMES is supported on future time code versions). In the WATCH/LAP function of the tape counter can function as a stopwatch to measure intervals without interfering with the normal tape timing operation.

Function Selection and Programming Key with LC Display

An additional, lockable key field for selecting and programming the functions of the audio and tape transport parameters as well as the command key functions is located below a hinged cover that conceals it from direct access. Associated with this key field and located above is an LC display with two rows of 20 alphanumeric characters each for status and parameter indication. Even "browsing" through the menu is possible because a cursor has been provided.

Multifunction Operating Center for Dynamic Access

Arranged between the primary and the secondary set of operator controls is an operating center for editing and programming (SHUTTLE and SET/CUE). The tape can be shuttled with variable speed in either direction - also directl from the PLAY function - by means of the cradle with defined zero setting. The tape rests on the heads during this function. If the selected shuttle speed is to be retained or stored in memory, simply press the central shuttle bar with your second finger.

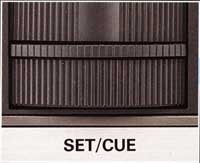

With the third element of the operating center, the SET/CUE wheel, two different functions can be selected. Designed as a flywheel it is used in the CUE function for fine-positioning the tape. It acts like an electric shaft with which the tape can be positioned analogously to the rotation on a "steering wheel".

In the SET function the same wheel is used for direct programming - with indication in the LC display - for entering the parameters, and for setting the varispeed, the tape counter, or a locator address.

Progamming made simple: The SET/CUE control is used to select operating parameters and it let's one search through the functions menu. The selected parameter or function is shown in the LC display (12.67 ips e.g.).

"Fingertip control" - for delicately sensitive operating. The Audio Archive: This is a very sensitive and fine positioning control - very helpful for indexing tapes.

Simple Programming Through Step-by-step User Guidance

Software programming with plain-text indication in the LC display is the key to very simply access to the highly versatile facilities of the STUDER A820. Five keys - four blue ones for the display position on the LCD and red memory button - as well as the SET wheel suffice for cmplete menu selection and parameter input. The blue keys are used for paging or down in the menu or for setting the cursor; the complete menu content is software-implemented and automatically generated by the processor control. All other keys of the STUDER A820, also the white ones in the programming key field or even the buttons of the remote control device - are soft keys and consequently freely assignable. It is, therefore, very easy to program the STUDER A820 to the user's requirements or to adapt it to changing environments. The same applies to tape transport functions and the audio parameters.

Facilities That Have Been Asked For Since the Invention of the Tape Recorder

It starts already with the power-on of a STUDER A820:

- Instead of an ON pilot lamp the LC display indicates the version of the loaded software.

- The selftest routine is activated. If any software or hardware fault is detected, its source is indicated on the LC display. Positive termination of the test routine is also acknowledged on the display.

- The STOP button is illuminated and the machine is ready for operation; the programmed line level is indicated on the LC display.

- The servo circuits can be activated as soon as a tape has been loaded into the STUDER A820. At this point cueing can be performed by simply rotating one of the tape pancakes by hand. The servo circuits are switched off as soon as the tape is pulled out of the tape path; the tape can be reinserted gently by pressing the STOP button.

- The STUDER A820 runs at four diferent speeds: 30 - 15 - 7.5 - 3.75 ips. One, two, three or all four speeds can be program-assigned to any key.

- With an absolute minimum of movement - with two finger touches - the operator can switch from PLAY to shuttle mode, vary the speed continuously, retain the desired speed, and stop the tape.

- From EDIT function the cutting positions are also only a question of fingertip control, the tape responds to even minute adjustments of the CUE wheel.

- Move the CUE position to the built-in scissors: press the (programmed) button, the processor takes care of the rest.

- Four different operating modes can be programmed for dump editing: either activated by the dump edit key or in combination with the PLAY/STOP keys and either with or without counter function. The tapes does not have to be pulled over the tacho roller because the processor scans and converts the tacho pulses of the capstan.

- In spooling mode the processor automatically detects the approaching end of the tape and reduces the spooling speed (with override possibility). The spooling speeds are freely programmable. A separate key can be programmed for slow spooling speed (library wind) in increments of 0.1 m/s to ensure that absolutely clean pancakes are produced if a tape is to be archived. The fast winding limits can also be programmed.

The Audio Archive: We love this level of control over spooling speeds, and run our library wind and fast spooling speeds at half or less of the default settings. This truly protects fragile tapes. The automatic detection of the approaching end of the tape prevents the reel with less tape (either the take-up or supply reel) from spinning at extremely high speeds as it might on other machines, which is both easier on the tape as well as safer for the operator.

- Four fader start operating modes can be programmed which means that no hardware modifications are necessary.

- The push button functions of the serial STUDER A820 remote control are also programmable; their assignment may even differ from the one for the local key field. Sockets for parallel control standard and an interface for SMPTE/EBU bus operation isoptionally availalble.

- Many additional functions and programming facilities have been incorporated in the STUDER A820 such as:

- Rollback with programmable time and functional sequence

- Loc Start with programmable function sequence

- Zero lock

- Address locator with 5 memories

- Reverse Play

- Varispeed, +/- 7 semitones, with selectable display format in "%", "semitones" or "ips".

"Fingertip Control" Has Been Extended to the Entire Audio Electronics

The audio parameters are aligned with an equally simple procedure for which not even a screwdriver is required. When selecting the menu, switch the cursor to AUDIO and continue up to the parameter block; modify the desired parameter with the SET/CUE wheel (the information is indicated on the display in hexadecimal form) and store it with the push of a button. That's all!

The same porcedure is used for programming the tape tension, spooling speeds, bias, and equalization for two typess of tape (A and B).

The Audio Archive: We take advantage of the alignment features daily. They allow us to switch between a variety of tape track formats rapidly. The electcronic alignment is highly repeatable and accurate (see the next section about digital storage), making routine alignments quick and simple, and we can monitor and adjust for changes in the frequency response as the playback heads wear and are relapped as part of their regular maintenance. The same rapid adjustments are true for the spooling speeds and tape tension, again allowing us to be as gentle as possible on fragile tapes.

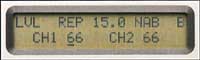

LCD image showing Reproduce level calibration from the audio calibration menu. Values shown are indicated in HEX for NAB equalization, tape sort B and 15 ips.

LCD image showing Play tension calibration from the tape deck calibration menu. Tension values are indicated in HEX for both motors left and right.

A serial interface RS 232/422 (SMPTE/EBU format) is available as an option for control purposes or for calibrating with a service computer.

Not only the customary functions such as mono/stereo change over, rehearse, and spot erase but also an exotic function such as skimming can be programmed. The latter can be used to activate a slight bias during reproduction in order to minimize the copying effect of tapes that have been archived for a long time.

The Audio Archive: There are only 3 STUDER machines that have the skimming capability: STUDER A820 MKII, A812 MKII, and A816. Studer was the only manufacturer to build this capability into their machines. Note that print-through erasure was patented by R. Herr of 3M (US Patent 2861133, filed 1949 Aug 01, granted 1958 Nov 18). In essence, skimming works by erasing the printed field in the smaller improperly oriented oxide particles on the tape, while not greatly affecting the field recorded in the longer, properly oriented oxide particles. Hence it only works on the original tape. Because it works via magnetism, it would be extremely difficult, if not impossible, to implement skimming using DSP.

Digital Storage for Accurate Reproducibility of All Parameters

Accurate reproducibility is achievable at all times because the parameters, particularly with respect to the audio electronics, are stored in digital form. The stored values can be retrieved for logging via the LCD, or they can be read out and stored externally via the serial interface.

Inside the machine the parameters are set without contacts by means of 8-bit D/A converters (resolution 256 steps per setting range).

Accurate, Stable, Compact, and Electronically Identifiable: The Modern Headblock of the STUDER A820 Generation

When a headblock is plugged into the STUDER A820, the master processor is automatically informed concerning its type and configuration. This method of electronic identification permits not only the use of a large variety of assemblies but also easy conversion and error-free adaptation.

The electronic section of the various headblocks feature high-quality integrated head preamplifiers for excellent signal-to-noise ratios.

The Audio Archive: Indeed, the tape head preamplifier is embedded in the headstack directly behind the heads. This makes for extremely short low-level signal cables from the head to the preamplifier, minimizing noise.

The design of the head shield which protects against magnetic fields has again been improved. The plug-in STUDER A820 headblocks feature an extremely rigid design and are equipped with their own die-cast aluminum alloy chassis.

The Audio Archive: The STUDER A820 is extremely well suited to archival work because of the quick and easy changeover of headblocks. If you ever inspect the STUDER A820 headblock in person, you will be impressed with both its heft as well as the quality of the CNC machine work. It is Swiss after all.

The tape path geometry has been carefully optimized; close head spacing, precision tape guidance - also directly in front of the capstan - and processor controlled interaction of the transport sequences ensure perfect tape travel.

But despite all these microelectronics the traditional work techniques have not been neglected; a cutting/splicing block and a tape list assembly for manual fade in/out have been provided.

The STUDER A820 head assembly is typically STUDER. Compact, rugged and manufactured with high precision. Close head spacing and ceramic guides are further highlights. The Audio Archive: Not shown are the optional precision calibrated external azimuth adjusters. These are especially useful for archival work because the exact azimuth values can be measured and logged as part of the technical metadata. The Audio Archive has two head-blocks equipped with this rare option.

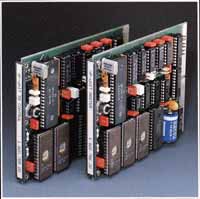

Plug-in Electronics - Simple and Convenient to Access

The complete electronics for processor control, tape transport logic, and audio electronics becomes conveniently accessible when the tape deck is tilted. A row of LEDs provides information on the individual supply voltages which are monitored by software.

Electronics for transport and audio are all of the plug-in type. The Audio Archive: The card cage is easily accessible making maintenance and system diagnosis quick and simple. Any repairs can often be accomplished by identifying and swapping the faulty card.

Multiprocdessor control for unequalled flexibility in recorder utilization.

Phase Corrected Audio Electronics

The STUDER A820 audio electronics achieves unsurpassed sound burst fidelity both in the record as well as the reproduction path because it has been carefully designed for ideal phase response.

The inputs and outputs are equipped with transformers; transformerless, balanced high performance amplifiers are available also.

For Synchronization Applications: The Time Code Version (TC)

The STUDER time code system for stereo recorders - for the first time presented with the A810 - is also implmented in the A820 TC versions. A high-precision working tool is available for video-audio / film-audio, and audio-audio interlocking wihcih in many situations can replace a far more expensive multi-channel recorder.

The STUDER time code system is based on center track recording of the SMPTE/EBU time code and physical sseparation of the audio and time code heads. The attenuation of cross talk between audio and time code signals achieved through this separation of the head functions is better than 90 dB. The time offset, resulting from the physical separation of the heads is compensated in a dynamic memory, as a function of the tape speed. This processor-controlled compensation works even in varispeed mode. precision synchronization between audio and time-code channels means that no time offset is required on the synchronizer and that recorded tapes can be splice-edited in the customary manner.

With or Without VU Meter Overbridge: The Version Depends on the Application

The concept of the VU meter overbridge is as flexible as you would expect on the STUDER A820.

In its most simple form it is a storage shell or a shelf with an additional monitor section.

The time code versions with VU channel units are equipped with a code channel control. For expanded synchronizing applications the overbridge also accomodates the local control unit (LCU) of the synchronizer TLS 4000.

VU Channel Control Via Command Data Bus

The channel controls of the VU units and of the time code channel are equipped with momentary push buttons and active function indicators consisting of differently colored LEDs. The simple and neat design, as as the large, back-illuminated output meters (programmable for VU or PPM characteristic) blends harmoniously withthe user-oriented handling concept of the processor-controlled STUDER A820 deck.

Standard and Optional Interfaces for Audio and Data Communication in the Studio of Tomorrow

The interfacing possibilities of a STUDER A820 are manifold. Both conventional parallel remote control and serial control by means of programmable remote functions are standard features.

The optional SMPTE/EBU bus interface (RS 232/422) offers universal facilities. For coordinated host system control to be implemented by the studio of tomorrow, the STUDER A820 is eminently suited because the internal control functions as well as the interaction with partner machines over the peripheral interfaces can be defined by software programming.

This is the Flexible and Future-Safe Concept by STUDER

The Audio Archive: So just how future-safe is the STUDER A820? The STUDER A820 can be remanufactured and upgraded to operate like new by Fred Thal at ATAE - just as the brochure states 20 years ago, the STUDER A820 was designed for extremely long service life. Not only that, but extremely powerful, modern control and diagnostic software is available today for STUDER machines from Studio Remotes at http://www.studio-remotes.com. You can monitor the tape tension in real-time! Try that with an Ampex ATR-102.

Broadcasting Version with Built-in Monitor Speaker

Broadcasting versions without VU meter overbridge feature a monitor speaker that is built into the tape transport cover. The individual audio channels as well as the CUE channel (time code track) can be monitored by means of additional push buttons located behind the headblock. The functions of this selector and of the headphone socket are jumper-programmable and can, therefore, be matched to the user's requirements.

STUDER A820 European Broadcast version without overbridge.

STUDER Master Recorder Service

Fred Thal, owner of ATAE, provides full service, rebuilds, and factory uppates to the STUDER A80, A800, A820 or A827 Master Recorders, as well as accessories, modifications, and custom hardware.

Fred is best reached via email:

afthal (at) gmail.com

Fred performs all the work on the STUDER A820 machines at The Audio Archive.

John French, owner of JRF Magnetic Sciences is a good resource for head reconditioning and lapping, or other headblock work. John provides prompt, courteous, quality service.

STUDER Control Software

As a testament to just how future-proof the original STUDER A820 design is, you can purchase modern control and real-time monitoring software from Studio Remotes

The STUDER List

This is a listserv that serves as the the de facto technical reference for Studer Master Recorders. The list is diligently moderated by Fred Thal, and has a very high signal-to-noise ratio.